How to Read Pump Curves for Centrifugal Pumps?

Views: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

Centrifugal pumps are essential in industrial and commercial systems. They move liquids efficiently, converting velocity into pressure. The flow they produce depends entirely on the system’s resistance, pipe layout, and liquid properties.

Understanding a pump curve is the first step to selecting the right pump. It shows how the pump behaves under different flow and head conditions. By analyzing the curve, we can predict efficiency, power consumption, and operating limits. Proper understanding prevents cavitation, vibration, and premature wear, saving both time and money.

What is a Centrifugal Pump Curve?

A centrifugal pump curve is essentially a performance map. It shows flow (Q) on the horizontal axis and head (H) on the vertical axis. Each curve may include multiple lines, such as:

Flow rate (L/min, m³/h, or GPM)

Total Dynamic Head (m or ft)

Efficiency (%)

Power consumption (kW or HP)

Net Positive Suction Head Required (NPSHr)

Advanced curves may include impeller diameters, motor speed (RPM), or minimum continuous stable flow (MCSF). Reading a pump curve helps engineers know exactly how the pump will perform under a specific system setup, even before installation.

| Curve Feature | Purpose |

|---|---|

| Flow rate (Q) | Volume the pump can move |

| Head (H) | Energy the pump adds to fluid |

| Efficiency | Energy effectiveness at each point |

| Power | Motor energy needed |

| NPSHr | Minimum inlet pressure to avoid cavitation |

Key Components of a Pump Curve

Flow Rate (Q)

Flow rate measures how much liquid the pump can deliver per unit time.

Low flow = high pressure

High flow = lower pressure

The system’s layout controls how much flow actually occurs. Even if a pump can provide 2000 L/min, pipe restrictions or high friction losses may reduce actual flow.

Head (H)

Head quantifies the energy a pump adds to the liquid. Total Dynamic Head (TDH) combines:

| Component | Description |

|---|---|

| Static Head | Difference between pump and discharge height |

| Suction Lift | Difference between fluid level and pump inlet |

| Friction Loss | Pressure lost from bends, valves, fittings |

TDH is critical for selecting the right pump. If friction is high or fluid is viscous, the pump must generate more head to overcome losses.

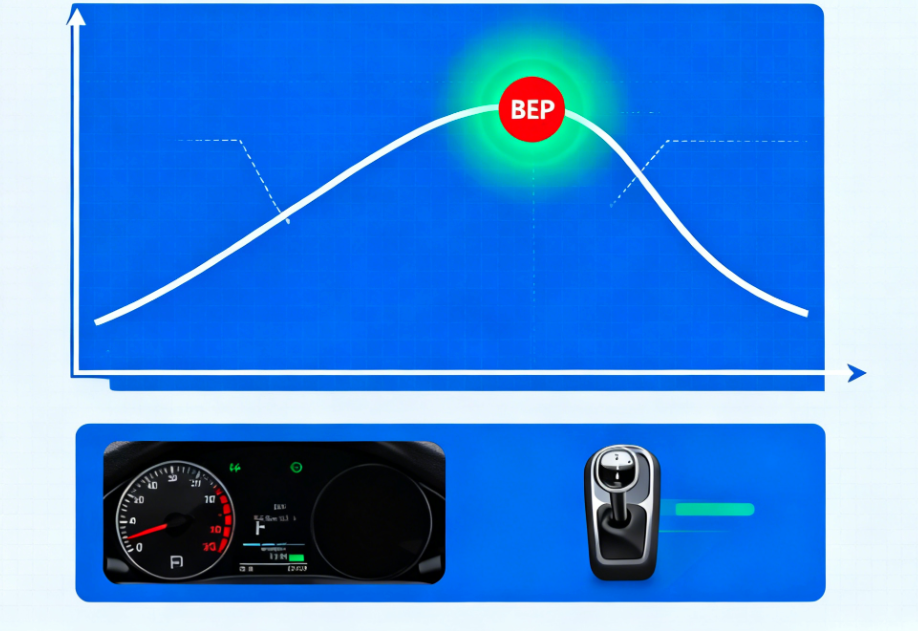

Best Efficiency Point (BEP)

The BEP is where a pump operates most efficiently. Near BEP:

Energy use is minimal

Pump parts experience the least stress

Axial and radial forces on the impeller are balanced

Running far from BEP can lead to cavitation, vibration, and wear. Think of it like a car: first gear is possible at high speed but damages the engine.

Power and Efficiency Curves

Pump curves often include ISO efficiency lines and ISO power lines. These allow engineers to estimate energy consumption for any duty point. If your duty point lies between 100 HP and 140 HP lines, the pump will consume roughly 120 HP.

Net Positive Suction Head Required (NPSHr)

NPSHr is the minimum inlet pressure the pump needs to avoid cavitation. NPSHa is what your system provides. Always make sure NPSHa exceeds NPSHr, ideally with a margin of 3–5 feet (1–1.5 m).

Impeller Diameter and Trimming

Impeller size directly affects flow and head:

Larger diameter = higher flow and head

Smaller diameter = lower flow and head

Trimming allows fine-tuning when system requirements change. Curves often show multiple impeller diameters for reference.

| Impeller Ø (mm) | Flow (L/min) | Head (m) |

|---|---|---|

| 175 | 1800 | 28.6 |

| 160 | 1600 | 25.0 |

| 145 | 1400 | 21.5 |

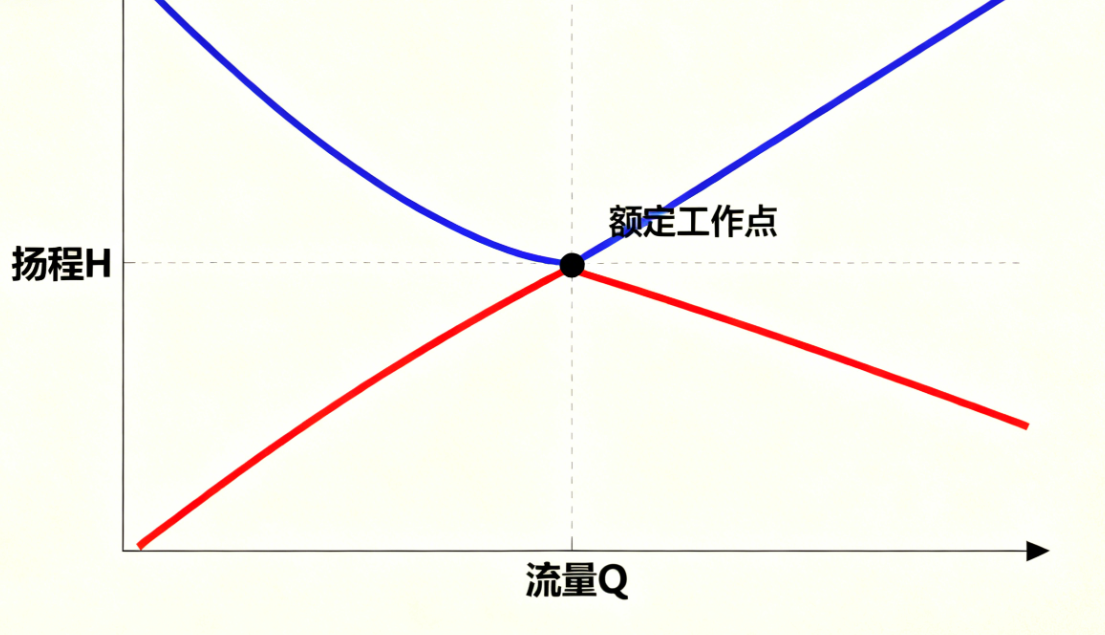

Rated Duty Point

The rated duty point is where the system resistance curve intersects the pump curve. It shows where the pump should ideally operate for efficiency and longevity.

How to Read a Centrifugal Pump Curve

Confirm pump speed and impeller diameter. Curves only apply at the specified RPM.

Locate shut-off head and run-out flow. Shown at curve endpoints.

Measure total dynamic head (TDH). Subtract suction gauge reading from discharge gauge reading.

Plot TDH on the curve. Intersection gives flow rate.

Check efficiency, power, NPSHr. Use ISO lines to interpolate.

Adjust operation if outside recommended range. Avoid extremes near shut-off or run-out.

Understanding Curve Shapes

| Curve Type | Characteristics | Suitable Applications |

|---|---|---|

| Steep Curve | High head at low flow | Pressure-focused |

| Flat Curve | High flow at low head | Volume-focused |

| Drop-Off Curve | Efficiency drops at low/high flow | NPSH-sensitive or high-risk |

Curve shapes guide pump selection and help troubleshoot real-world problems.

Practical Applications of Pump Curves

Selecting the Right Pump

When choosing a centrifugal pump, it is essential to match the flow rate and head to the specific needs of your system. The liquid being pumped also matters—its density, viscosity, and temperature can all affect performance. One key consideration is ensuring that the Net Positive Suction Head available (NPSHa) exceeds the Net Positive Suction Head required (NPSHr) by the pump, ideally with a small safety margin. Operating the pump close to its Best Efficiency Point (BEP) is also important, as this helps minimize energy consumption and reduces wear on pump components.

Optimizing Pump Performance

To maintain optimal performance, it is best to operate the pump near its BEP whenever possible. If system requirements change over time, impellers can be trimmed or the pump speed adjusted to better suit the application. Pipe friction also plays a role in efficiency—using smoother bends, wider pipes, and reducing unnecessary fittings can help minimize energy losses. Regular maintenance, including checking bearings, seals, and impeller conditions, ensures that the pump continues to operate efficiently and reliably.

Troubleshooting Using Pump Curves

Pump curves are invaluable for diagnosing issues in the field. Cavitation, for instance, often manifests as a “gravel-like” noise and can indicate low suction pressure or high fluid temperature. Monitoring suction and discharge gauges allows operators to verify whether the pump is operating at the expected point on the curve. If the pump shows signs of vibration, reduced flow, or lower-than-expected efficiency, comparing the actual operating point to the pump curve can help identify problems. Adjustments to the system or the pump itself—such as increasing suction pressure, modifying pipework, or correcting impeller trim—can restore proper operation and prevent long-term damage.

Common Mistakes When Reading Pump Curves

One of the most frequent mistakes is ignoring the system resistance curve. Even a well-designed pump may perform poorly if the system’s flow resistance is not considered, leading to incorrect flow or pressure predictions. Operating the pump far from its Best Efficiency Point (BEP) is another common error. Pumps running too far left or right on the curve experience excessive wear, vibration, and energy waste.

Neglecting Net Positive Suction Head (NPSH) requirements can cause cavitation, which damages impellers and reduces pump lifespan. Another mistake is using pump curves for fluids with different viscosity or specific gravity than what the curve is based on, usually water. This can lead to overestimating flow or underestimating required power. Finally, misinterpreting power or efficiency lines often confuses operators. The actual energy consumption and efficiency may differ if the curve is read incorrectly, especially when interpolating between ISO lines or varying impeller diameters.

FAQ

Q: What is a centrifugal pump curve?

A: A centrifugal pump curve is a graphical representation of how a pump performs in terms of flow, head, efficiency, and power at different operating points.

Q: Why is the Best Efficiency Point (BEP) important?

A: The BEP shows where a pump operates most efficiently, minimizing energy use, reducing wear, and preventing cavitation.

Q: How do I find the flow rate from a pump curve?

A: Measure the total dynamic head (TDH) from your system and plot it on the curve; the intersection with the curve gives the flow rate.

Q: How does impeller diameter affect pump performance?

A: A larger impeller increases flow and head, while a smaller impeller reduces them; trimming allows fine adjustments to meet system requirements.

Q: Can pump curves be used for fluids other than water?

A: Yes, but you must adjust for viscosity and specific gravity; using a water-based curve without adjustment can lead to inaccurate performance predictions.

Conclusion

Understanding how to read centrifugal pump curves is essential for selecting, operating, and maintaining pumps efficiently. By analyzing flow, head, efficiency, NPSHr, and impeller characteristics, engineers and operators can prevent issues like cavitation, excessive wear, and energy waste. Proper interpretation ensures pumps perform reliably, meet system demands, and deliver optimal energy efficiency.

Laiko Pump (Zhejiang) Co., Ltd. brings over 34 years of industry experience and technological expertise inherited from Zhejiang DAYUAN Pumps Industrial Co., Ltd. With a comprehensive product line and leading manufacturing capabilities, Laiko Pump provides high-quality centrifugal pumps and technical support to help customers select and operate pumps at peak efficiency, backed by decades of proven engineering knowledge.

Product Category

Contact Us

laiko@laikopump.com

No. 18 Zhongxing Ave, Zeguo, Wenling, Zhejiang