How is a centrifugal pump different from a normal pump?

Views: 0 Author: Site Editor Publish Time: 2025-11-21 Origin: Site

Pumps are essential in almost every industry, from water supply and irrigation to chemical processing and oil transfer. Choosing the right pump can save energy, reduce maintenance, and ensure smooth operations. Among the most common types are centrifugal pumps and normal pumps (positive displacement pumps). While both move fluids, they operate on very different principles, handle fluids differently, and are suited for different applications. Understanding these differences is crucial for selecting the right equipment for your system, whether it’s high-volume water circulation or precise chemical dosing.

This article explores the key differences between centrifugal pumps and normal pumps, covering working principles, flow behavior, fluid handling, suction capability, maintenance, applications, and efficiency.

1. Working Principle

Centrifugal Pump:

Uses a rotating impeller to transfer rotational energy from the motor to the fluid.

Fluid enters the pump at the center, called the impeller eye, and is thrown outward along the vanes by centrifugal force. This action increases both the velocity and pressure of the fluid.

The flow rate of a centrifugal pump depends on impeller diameter, rotational speed, and system resistance, which means changes in piping or backpressure can directly affect its performance.

These pumps are commonly used for transporting low-viscosity liquids like water, solvents, and light oils, making them ideal for industrial water supply, irrigation, and chemical transfer systems.

Normal Pump (Positive Displacement):

Moves a fixed volume of fluid during each cycle, independent of system pressure.

Fluid is trapped in a chamber or cavity and mechanically forced into the discharge pipe, ensuring consistent flow regardless of variations in backpressure.

Positive displacement pumps are well-suited for high-viscosity fluids, thick oils, slurries, and fluids containing solids, often found in food processing, oil extraction, or chemical dosing applications.

Types include gear pumps, piston pumps, diaphragm pumps, and rotary lobe pumps, each designed for precise flow control or high-pressure delivery.

Key Difference:

Centrifugal pumps rely on velocity and pressure changes to move fluid, so flow varies with system conditions. Normal pumps, in contrast, push a fixed volume consistently, maintaining steady output even under fluctuating pressure or viscous conditions. This fundamental difference makes centrifugal pumps ideal for high-flow, low-pressure operations, while positive displacement pumps excel in high-viscosity, high-pressure, or precise dosing applications.

2. Flow Rate and Pressure Behavior

| Feature | Centrifugal Pump | Normal Pump |

|---|---|---|

| Flow Rate | Varies with system pressure; flow decreases if resistance or backpressure rises | Remains constant regardless of changes in pressure |

| Pressure Handling | Performance drops under high pressure; efficiency sensitive to flow conditions | Can maintain high pressures; output not affected by system |

| Priming Requirement | Requires priming before start-up; cannot pump air or run dry | Can self-prime in many designs; creates suction naturally |

| Best Applications | Low-viscosity fluids, high-volume pumping, water circulation, HVAC, irrigation | High-viscosity liquids, slurries, chemical dosing, oil transfer |

Centrifugal pumps are optimized for high-flow, low-viscosity systems where the main goal is moving large volumes efficiently. Positive displacement pumps are better when flow consistency, high pressure, or viscosity handling is critical.

3. Fluid Viscosity and Shear Sensitivity

Centrifugal Pump:

Works best with low-viscosity fluids such as water, light oils, and most solvents.

High-viscosity liquids increase resistance, causing the impeller to work harder, which reduces efficiency and may lead to overheating or wear.

The high-speed rotation of the impeller can damage shear-sensitive fluids, including emulsions, suspensions, or delicate biological liquids, because the fluid experiences rapid velocity changes.

In applications like chemical processing, wastewater handling, or water circulation, centrifugal pumps are ideal for fluids that are thin and uniform.

Normal Pump (Positive Displacement):

Designed to move thicker, viscous fluids efficiently, including slurries, pastes, heavy oils, and fluids with suspended solids.

The internal flow is slow and controlled, so there is minimal shear, keeping shear-sensitive products intact.

Often used in food processing, pharmaceutical, and oil industries, where the product’s texture or composition must remain unchanged.

Can handle fluids that would strain or damage a centrifugal pump, providing consistent, safe pumping under high-viscosity conditions.

Centrifugal pumps are excellent for high-volume, low-viscosity fluids, but less effective for thick or delicate liquids. Positive displacement pumps shine in viscous, shear-sensitive, or slurry applications, offering reliability and protection for the fluid.

4. Suction and Priming Capability

| Feature | Centrifugal Pump | Normal Pump |

|---|---|---|

| Suction Lift | Cannot lift liquid on its own; must be primed before operation | Can create a vacuum and lift fluid from below or above source |

| Air Handling | Air in the system reduces performance; cannot pump air-liquid mix efficiently | Many designs tolerate air entrainment and variable suction |

| Startup Requirement | Requires manual or external priming | Can often self-prime, ideal for intermittent operation |

Centrifugal pumps rely on a fully primed suction line to function. If the pump runs dry or air enters the system, it may **lose efficiency or get damaged. They are less suitable for applications above the fluid source, such as wells or tanks positioned lower than the pump.

Positive displacement pumps, on the other hand, can generate a vacuum at the inlet, allowing them to self-prime and lift fluid from various levels. This capability makes normal pumps ideal for suction lift, intermittent operation, or remote locations where fluid availability is inconsistent. Industries like agriculture, construction, and wastewater management often rely on self-priming positive displacement pumps, whereas centrifugal pumps dominate large-scale water circulation and industrial fluid transport.

5. Mechanical Design and Maintenance

Centrifugal Pump:

Built with few moving parts, usually just an impeller, a shaft, and a casing.

The simple design allows for easier assembly, inspection, and repair, making it ideal for operators with limited maintenance resources.

Generally requires less frequent maintenance, since wear is slower when pumping clean, low-viscosity fluids.

Initial cost is typically lower than positive displacement pumps, making centrifugal pumps attractive for large-scale water supply, HVAC systems, and irrigation networks.

Replacement parts, such as impellers or seals, are usually readily available and straightforward to install, reducing downtime.

Normal Pump (Positive Displacement):

Features a more complex design with multiple moving components, such as gears, pistons, vanes, or diaphragms, depending on type.

The complexity allows it to handle high-viscosity fluids, slurries, and shear-sensitive materials, but also requires regular maintenance to maintain performance.

Rotary and reciprocating designs need careful inspection of internal clearances, seals, and bearings to prevent leaks or performance loss.

Maintenance costs and labor are generally higher, but the pump’s robustness and ability to manage difficult fluids justify the investment in industrial, chemical, and food processing environments.

Proper maintenance ensures the pump can deliver consistent flow and pressure over long operational periods, even under demanding conditions.

Key Difference:

Centrifugal pumps are simpler, lower-cost, and easier to maintain, ideal for high-flow, low-viscosity applications. Positive displacement pumps, while more complex and maintenance-intensive, are highly versatile, capable of handling challenging fluids, solids-laden liquids, and high-pressure requirements.

6. Application Comparison

| Application Type | Centrifugal Pump | Normal Pump |

|---|---|---|

| Water supply & circulation | Yes | No |

| Irrigation | Yes | No |

| Chemical transfer (low-viscosity) | Yes | No |

| Oils, slurries, pastes | No | Yes |

| Accurate dosing | No | Yes |

| Shear-sensitive fluids | No | Yes |

Centrifugal pumps are preferred for high-flow, low-viscosity applications, such as water circulation, irrigation, or light chemical transfer.

Normal pumps are better suited for viscous, solids-laden, or shear-sensitive fluids, and applications that require precise flow control or accurate dosing.

7. Efficiency and Energy Use

Centrifugal pumps are most efficient when operating within their optimal speed and pressure range. Flow rates, head, and system resistance outside this range can significantly reduce performance. They are generally energy-efficient for low-viscosity, high-volume applications, such as water circulation, HVAC systems, and irrigation networks. Less mechanical complexity and fewer moving parts help reduce friction losses, contributing to lower operational costs. However, when pumping thicker fluids or high-viscosity liquids, centrifugal pumps require more energy to overcome resistance, causing efficiency to drop and potentially increasing wear on the impeller and casing.

Normal pumps (positive displacement) are less sensitive to changes in pressure or viscosity. They maintain a constant flow and relatively stable efficiency, even under varying system conditions. Positive displacement pumps may consume more energy at high speeds compared to centrifugal pumps, but their ability to handle viscous or solids-laden fluids without losing flow often makes them more suitable for demanding industrial applications.

In summary, centrifugal pumps are cost-effective for large-scale, low-pressure systems, whereas normal pumps are reliable for variable, high-pressure, or high-viscosity operations.

8. Summary Table of Differences

| Feature | Centrifugal Pump | Normal Pump |

|---|---|---|

| Principle | Kinetic energy via impeller | Fixed volume displacement |

| Flow | Variable, depends on pressure | Constant, independent of pressure |

| Pressure | Moderate; drops if load increases | High; stable under load |

| Viscosity | Best for thin liquids | Handles thick or viscous liquids |

| Shear | High; can damage sensitive fluids | Low; safe for delicate fluids |

| Suction | Needs priming | Can self-prime |

| Maintenance | Simple, fewer parts | Complex, more parts |

| Applications | Water, HVAC, irrigation, chemicals | Oils, slurries, food, pharmaceuticals |

FAQ

Q: What is the main difference between a centrifugal pump and a normal pump?

A: A centrifugal pump relies on impeller rotation to increase fluid velocity and pressure, while a normal (positive displacement) pump moves a fixed volume of fluid consistently regardless of system pressure.

Q: Can centrifugal pumps handle viscous or thick fluids?

A: No, centrifugal pumps are best for low-viscosity fluids, as high-viscosity liquids reduce efficiency and may cause overheating or impeller wear.

Q: Are normal pumps suitable for shear-sensitive fluids?

A: Yes, normal pumps operate at lower speeds and generate minimal shear, making them ideal for delicate fluids such as emulsions, biological liquids, or food products.

Q: Do centrifugal pumps require priming before operation?

A: Yes, centrifugal pumps must be primed and cannot pump air or run dry, otherwise performance drops or the pump may be damaged.

Q: Can normal pumps self-prime?

A: Many positive displacement pumps can self-prime and lift fluid from below or above the source, making them suitable for suction lift or intermittent applications.

Conclusion

Selecting the right pump type can significantly impact operational efficiency, energy consumption, and system reliability. Centrifugal pumps excel in high-flow, low-viscosity applications, while normal pumps handle high-viscosity, shear-sensitive, or solids-laden fluids with consistent flow and pressure. Understanding these distinctions helps engineers and facility managers make informed decisions.

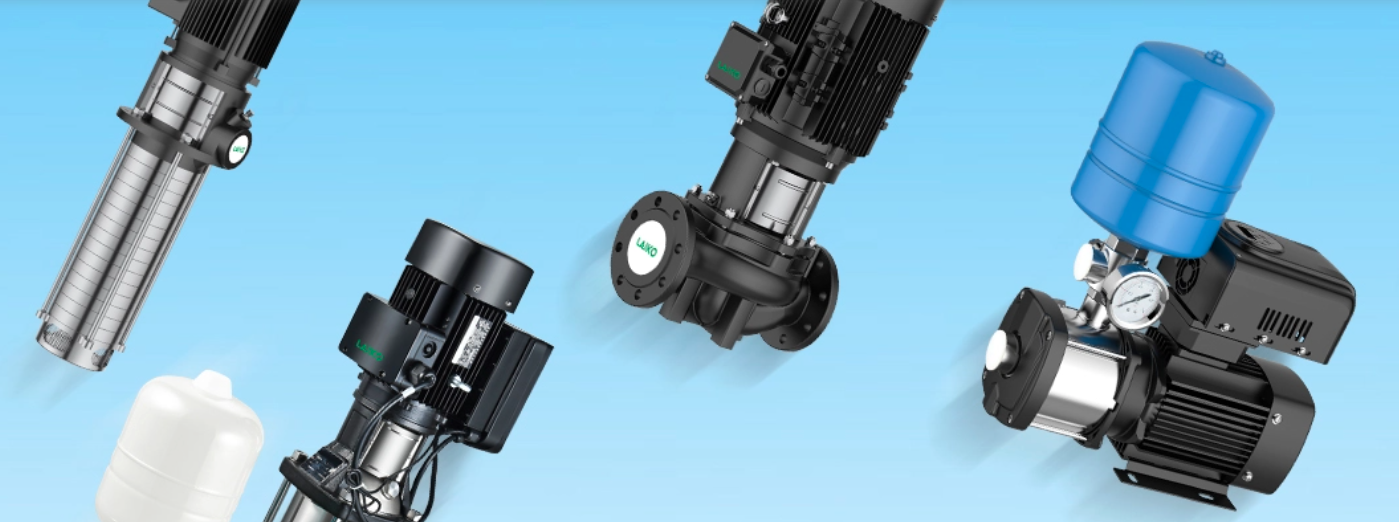

For reliable, high-performance pumping solutions, Laiko Pump (Zhejiang) Co., Ltd. offers a wide range of centrifugal and positive displacement pumps tailored to diverse industrial needs. Their products combine advanced engineering, durability, and efficiency, making them a trusted partner for water supply, chemical processing, food production, and more. Choose Laiko Pump for pumps designed to keep your operations running smoothly.

Product Category

Contact Us

laiko@laikopump.com

No. 18 Zhongxing Ave, Zeguo, Wenling, Zhejiang